TERiS is developing a technology platform for the realistic generation and analysis of tire wear. Through interdisciplinary collaboration among several Fraunhofer Institutes, a holistic approach is being created for sustainable material development, environmental assessment, and emission forecasting.

Tire wear is one of the largest sources of traffic-related fine dust emissions and significantly contributes to microplastic pollution. The upcoming Euro 7 standard will, for the first time, define limits – but existing test methods do not capture particle properties or their environmental impacts.

What TERiS Aims to Achieve

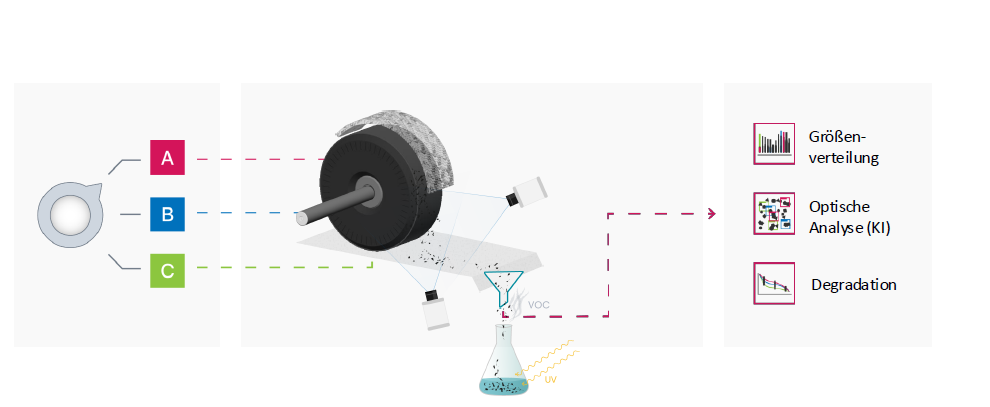

The project »TERiS – Technology Platform for Tire Wear and its Emission Identification in Road Traffic« is creating a platform for the standardized generation, analysis, and evaluation of realistic tire wear. The goal is to develop more environmentally friendly materials and to provide a solid basis for emission forecasting.

Realistic Wear – Controlled Generation

At the core of the project is a newly developed wear-testing machine that generates realistic rubber abrasion under controlled laboratory conditions. Friction surfaces are captured optically and analyzed using AI – a core competence of Fraunhofer IGD. Particle classification allows predictions of size distribution and serves as a foundation for developing tire materials with reduced pollutant emissions.

Simulation and Evaluation of Emissions

Degradation analysis takes place under realistic environmental conditions using new weathering and analysis methods. For the first time, this yields reliable data for ecotoxicological assessments and simulation-based emission forecasts for entire vehicle fleets.

Interdisciplinary Research Approach

TERiS combines the expertise of four Fraunhofer Institutes: LBF (wear-testing machine and weathering), ICT (abrasion characterization and emission forecasting), IWM (friction and particle models), and IGD (AI-based optical analysis).

Together, they are creating a solution that covers the entire value chain – from material development to digital vehicle simulation – going far beyond existing research efforts.

Fraunhofer Institute for Computer Graphics Research IGD

Fraunhofer Institute for Computer Graphics Research IGD