Detecting unexploded ordnance

Fraunhofer IGD incorporates “UXO Garden” into Digital Ocean Lab

Clearing the seabed of unexploded ordnance has become a political imperative. The focus is on the development of efficient systems for the detection of ammunition and explosives dumped in the oceans. Since last year, an underwater test field has been in operation off the coast of Nienhagen, where suitable technologies are being developed. Fraunhofer IGD is further expanding the Digital Ocean Lab and will be holding two workshops (November 17th) on the topics of the new “UXO Garden” and of calibration as part of the Rostock Ocean Convention.

Rostock: According to the German Federal Environment Agency, around 1.6 million tons of discarded munitions dating back to the Second World War are still lying in German waters. But it is not only uncontrolled explosions that pose a danger. Over time, the volatile substances in the munitions can enter the water column and, from there, the food chain. With the growing political will to recover and disarm explosive devices, the question is increasingly being asked: How can contaminated sites be detected and cleared efficiently and safely? The Fraunhofer Institute for Computer Graphics Research IGD is currently working on solutions with a number of partners in the Digital Ocean Lab (DOL).

Scientifically proven test field for survey companies

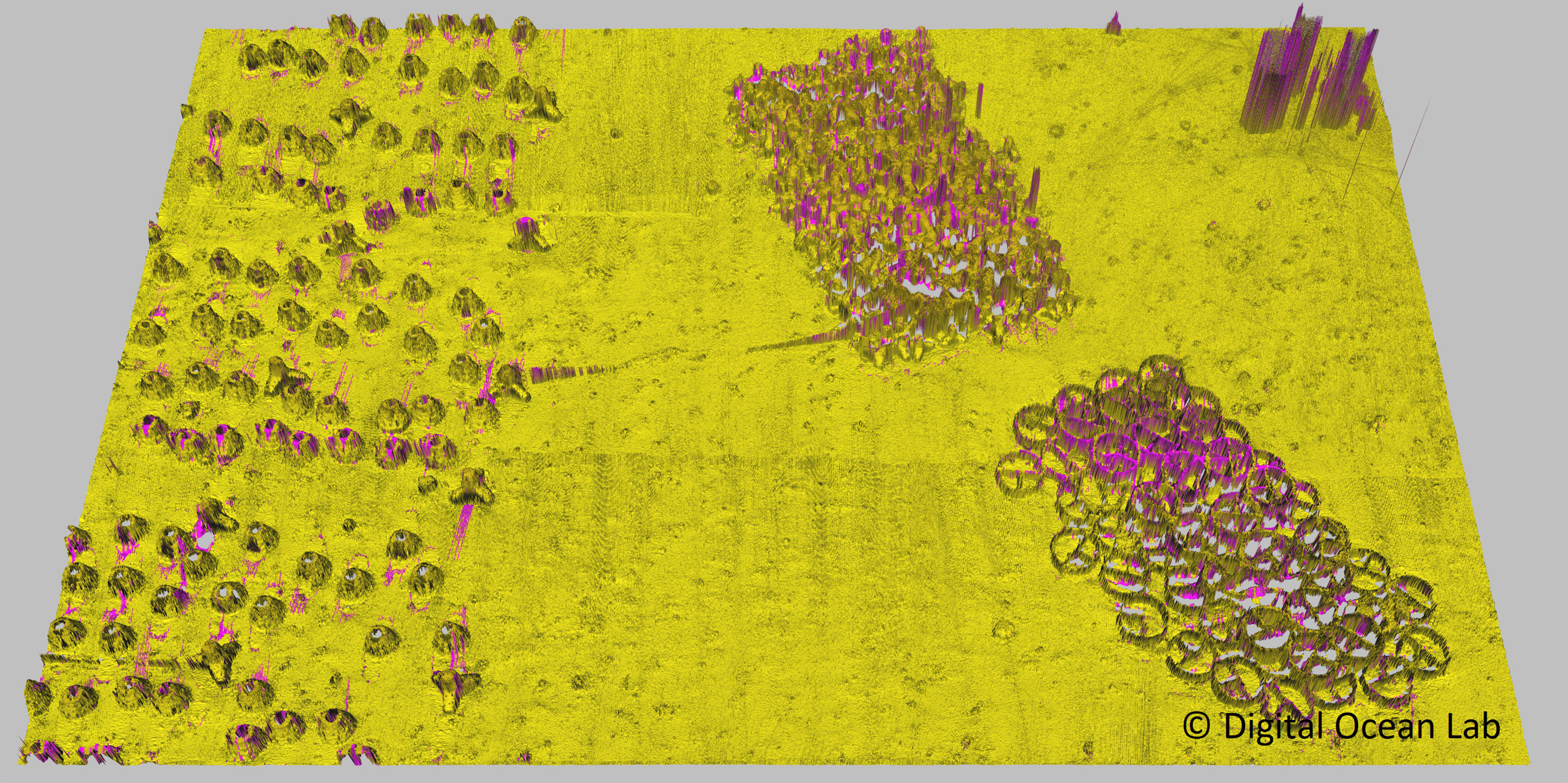

The “UXO Garden” is being created for this very purpose as part of the DOL. The acronym UXO stands for Unexploded Ordnance. Objects with a magnetic field that has been measured and calibrated in the laboratory and special non-magnetic dummies are located in the newly designated area on the seafloor to serve as test sites for marine survey companies and academic research partners. The equipment on hand also includes current meters, wave measuring buoys and a multibeam echo sounder. Dr. Peter Menzel, head of the Digital Ocean Lab: “Not only is there a demand for the detection and classification of contaminated sites, accurate to the nearest centimeter, but companies can also train here in the safe recovery of multiple explosive devices piled on top of each other.”

One of these research partners is SENSYS, a survey company based in Bad Saarow. Managing Director Wolfgang Süss explains their interest: “For us as a sensor manufacturer, the Digital Ocean Lab is a crucial testing ground for bringing our solutions into line with customer requirements. It enables us to compare technologies in terms of performance, handling and effectiveness.”

Precise calibration of the metrology

In the context of munitions detection, systems calibration obviously plays an important role. But this has so far been a challenge for survey companies: to determine the deviation of a survey instrument, they need reference to known structures on the seafloor. The “Calibration Objects for Multibeam and Sidescan Sonar in the DOL” workshop at the Rostock Ocean Convention is the framework within which the Fraunhofer Smart Ocean Technologies research group is pursuing solutions. Together with stakeholders from the maritime sector, the group is collating and defining requirements for a future calibration field in the Digital Ocean Lab. The key questions to be answered here concern the sizes, shapes, composition and material of the calibration bodies. In addition to the common relative calibration methods, it is intended that the field should also allow absolute calibrations, which are difficult to realize offshore.

Four Fraunhofer institutes are currently collaborating in the interdisciplinary SOT research group of the Fraunhofer-Gesellschaft Smart Ocean Technologies and, at the same time, using the DOL for their practice-oriented solution development.

Plans for a “Cable Garden”

The addition of a “Cable Garden” to the Digital Ocean Lab is planned for next year. As with the UXO Garden, systems for tracking data cables or power lines can be developed and expanded there. “Because these infrastructures are extremely vulnerable, effective technologies for monitoring as well as maintenance are imperative,” adds Dr. Menzel. “Companies that wish to validate their research or test their technology will find a suitable facility here at the DOL. We also provide scientific support for such tests and advise on the best way to carry them out.”

Further information:

- Digital Ocean Lab (igd.fraunhofer.de)

- Rostock Ocean Convention

- Fraunhofer Smart Ocean Technologies Research Group (smart-ocean.fraunhofer.de)

Fraunhofer Institute for Computer Graphics Research IGD

Fraunhofer Institute for Computer Graphics Research IGD