Smart quality assurance

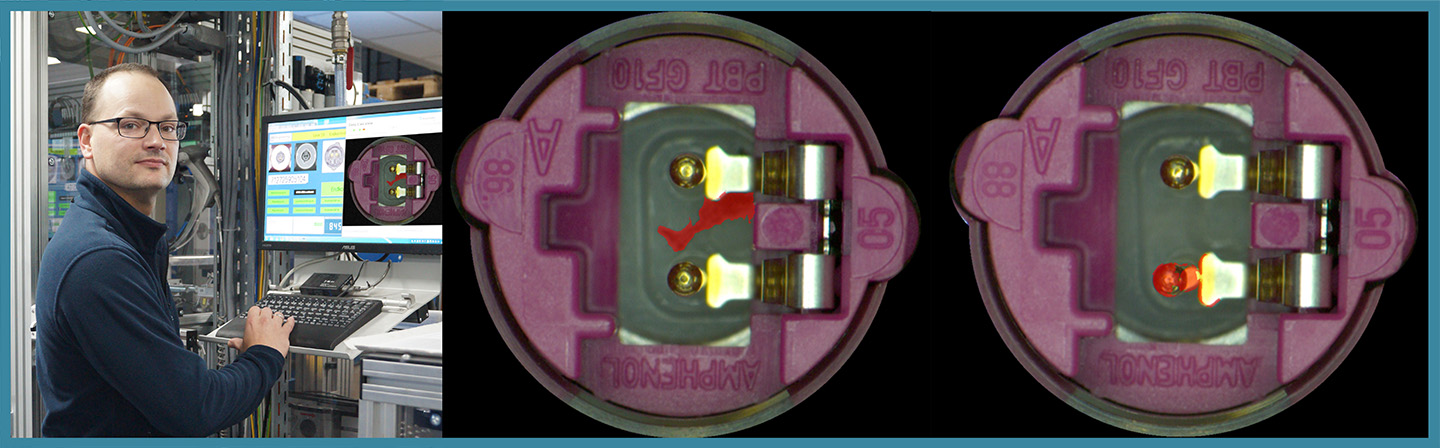

Fraunhofer IGD has developed AEOLIA, a software solution for the visual inspection of airbag gas generators. It saves time and money in quality assurance. ZF Airbag Germany plans to roll out the final inspection software to further production sites worldwide.

The ZF Airbag Germany factory in the State of Mecklenburg-Western Pomerania produces more than 100,000 airbag gas generators daily for customers around the globe. As safety-critical components, they are subject to strict quality control. Any checks and inspections must therefore be extremely reliable and accurate. The vehicle component suppliers tasked Fraunhofer IGD with the development of software that minimizes the need for manual follow-up checks, as these cause delays—and additional expense.

Reliable, timely quality checks

The AEOLIA (Automatic End-Of-Line Image Audit) software has a pseudo-defect rate of less than 0.1 percent. In other words, it rarely delivers false positives for the component images it analyzes. As a result, manual inspections of parts identified as possibly defective are reduced to a minimum. Furthermore, the solution is capable of checking images at very high speed. Once a potentially faulty part on the assembly line has been identified, an alert is sent to the production system’s PLC, and the part is removed for a follow-up inspection—with no disruption to ongoing manufacturing activities.

Smart, flexible software

AEOLIA is based on a tailored version of the Gaussian mixture model, a statistical method of calculating probability. The software learns the normal distribution in the appearance of any given product, and can then pick out anomalies. The learning process is based on images of components known to be without defects. Using this approach, quality assurance professionals can also quickly teach the software to evaluate new product variants.

Worldwide roll-out

Following a successful pilot phase, AEOLIA went through almost two years of further validation to ensure the required performance. Step by step, the Fraunhofer-developed solution has been leveraged to support the software already in use, and is now deployed on multiple production lines at the factory in Laage. ZF Airbag Germany is currently preparing to roll it out to facilities in Mesa (U.S.A.), Xian (China) and Aschau am Inn (Germany). Fraunhofer IGD is providing advice on implementation, is localizing the software, and will provide ongoing service and support.

Fraunhofer Institute for Computer Graphics Research IGD

Fraunhofer Institute for Computer Graphics Research IGD