Quantitative reliability analysis

Risk evaluation: Fraunhofer software takes FMEA to the next level

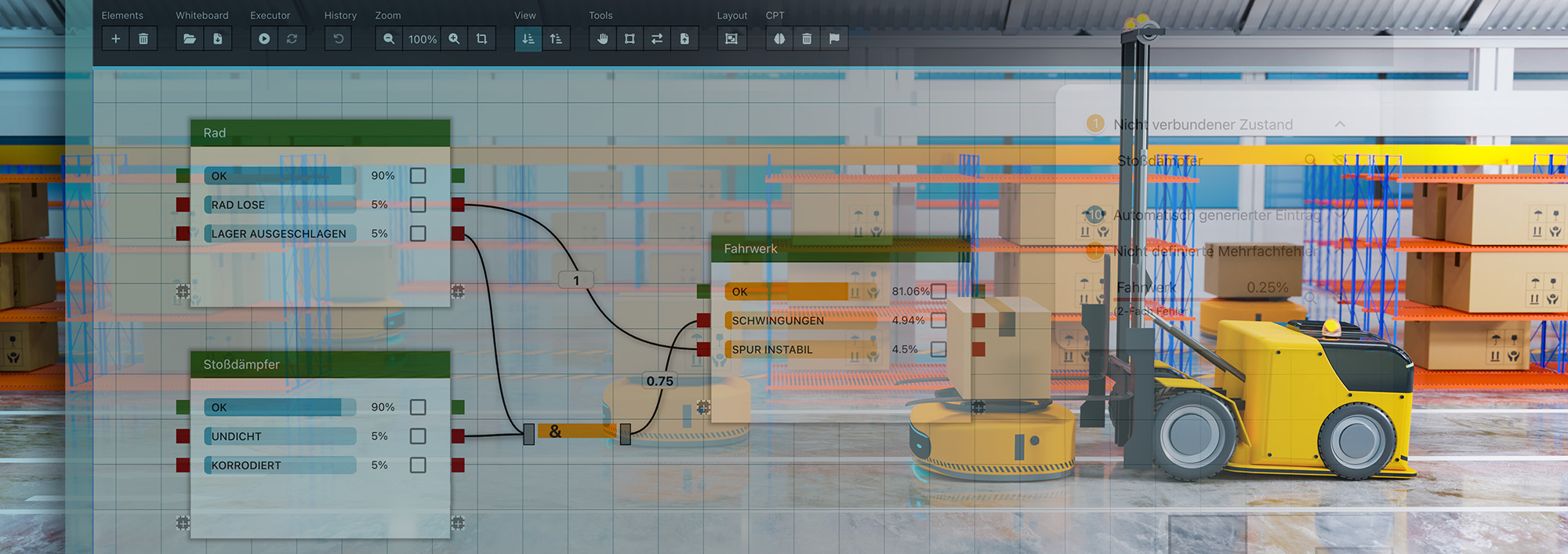

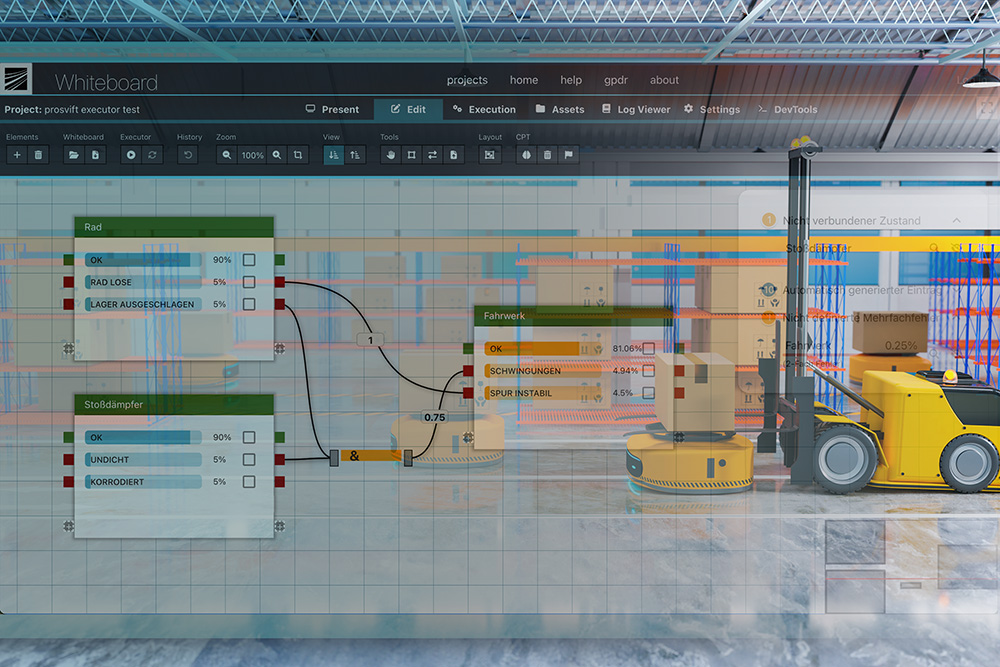

Autonomous vehicles in intralogistics and machine tools in industrial production are notorious for their susceptibility to faults and to failures of individual devices and components. It is therefore all the more important for manufacturers that they should be able to estimate the probability of such faults occurring in order to optimize the design of technical systems with regard to operational and process reliability. In proSVIFT, the research team at Fraunhofer IGD has developed a new tool based on probabilistic Failure Mode and Effects Analysis (FMEA) that can be operated intuitively. It enables users to reduce production downtime, to mitigate critical effects and to avoid resulting costs.

(Darmstadt) A bolt has worked its way loose, and the wheel of the driverless transport vehicle is in danger of coming off. The journey it was on is delayed, and so are the processes further down the line. It’s a realistic scenario that every business owner wishes to avoid. In a joint project with the Fraunhofer Institute for Structural Durability and System Reliability LBF, researchers at the Fraunhofer Institute for Computer Graphics Research IGD have designed a technology that takes the previous form of probabilistic FMEA based on Bayesian networks to the next level. By means of application-oriented visualization, the Fraunhofer team has enhanced the user-friendliness of probabilistic FMEA and thereby translated the methodological concept into practical application.

In addition to its original field of application in intralogistics, the software can also be used in all other areas of product development in which reliability and safety assessment in technical systems is relevant – for example, in the automotive industry.

Clear graphical representation

“Our solution combines different tools and simplifies the modeling as well as the assessment of hazard potentials,” explains Lena Cibulski, project manager for Fraunhofer IGD. “It minimizes the need for expertise in the field of FMEA and reliability theory as well as for software operating skills. In addition, our tool provides support in systematics, for example by flagging up previously unspecified (conditional) probabilities.”

The technology also facilitates the move from qualitative to quantitative risk assessment. Professor Jörn Kohlhammer, Head of the Information Visualization and Visual Analytics Department: “Qualitative risk assessment is based more on observations and is descriptive in nature. The Fraunhofer evaluation, on the other hand, is data-based and spells out the risks – their probabilities as well as their consequences. This is particularly important in sectors where safety is a key consideration, such as the aviation industry.”

Practical application: The next step

What are the errors that most frequently lead to failures or critical situations? What are the key levers for risk reduction? Does an additional sensor as a diagnostic option bring the desired success, or do false positive error messages lead to avoidable downtimes? The software helps to find the right balance between the conflicting requirements for safety and uninterrupted operation, thus minimizing costs.

In a follow-up project with the Fraunhofer LBF, Cibulski and Kohlhammer are establishing even closer ties with practice. Modeling will then no longer be based solely on input from the engineer, but also on evaluation of live data, thus intensifying condition monitoring during operation. “Our aspiration is to align research as closely as possible to the needs of companies,” adds Cibulski. “That’s why we are looking for industrial partners willing to integrate the technology into their processes.”

Experience live at the HANNOVER MESSE

The research team will be demonstrating the proSVIFT software at HANNOVER MESSE between 17th and 21st April 2023. It is the result of a joint project with the Fraunhofer Institute for Structural Durability and System Reliability LBF, which is part-funded by the Otto von Guericke consortium of industrial research associations (AiF) under the auspices of the German Federal Ministry of Economics and Climate Protection (BMWK).

Fraunhofer Institute for Computer Graphics Research IGD

Fraunhofer Institute for Computer Graphics Research IGD