Fraunhofer IGD optimizes Cuttlefish® 3D printing driver for Stratasys Polyjet applications

Fraunhofer IGD, the leading international research institute in Applied Visual Computing, has optimized its Cuttlefish® 3D printer driver for Stratasys PolyJet™ 3D printing, and is working collaboratively with Stratasys on future software enhancements.

Full-color, multi-material PolyJet 3D printing brings incredible realism to product designers and other creative professionals, with up to eight materials printed in one work step. Fraunhofer’s Cuttlefish software package first began supporting PolyJet systems in 2017 via the GrabCAD™ Voxel Print™ interface. Fraunhofer IGD has now improved existing and added new algorithms, which enables companies to save costs while producing prints with better geometric and color accuracy.

Philipp Urban, Head of 3D Printing Technologies at the Fraunhofer Institute for Computer Graphics Research IGD, explains the role played by Cuttlefish®: “When it’s an issue of optimization for mass production, specific color requests or degrees of translucency, nesting or individual color calibration, that’s where we come in.”

Since 2014, Urban’s team has been developing software that makes it possible to work with multiple print materials at the same time to exactly reproduce the geometry and colors (including translucencies and fine shading transitions) of the original and to simulate the printout on the screen in advance. Cuttlefish® has already played its part in producing hundreds of thousands of high-quality PolyJet 3D prints for customers in a range of industries.

“Our collaborative partnership has been designed for the long term, with the aim of enabling Stratasys customers to fully exploit the technical potential of their printers,” Urban said.

Perfect basis for 3D printing research

Universities and research institutes that use PolyJet printers as part of their 3D printing research can use the plug-in functionality of Cuttlefish® that allows them to conveniently integrate their own methods and software components into the Cuttlefish® workflow. It means that researchers do not have to program everything themselves but can build on the expertise already available at Fraunhofer IGD. This makes Cuttlefish® an optimal basis for further research in the field of 3D printing.

Cinema-ready level of performance from Stratasys and Cuttlefish®

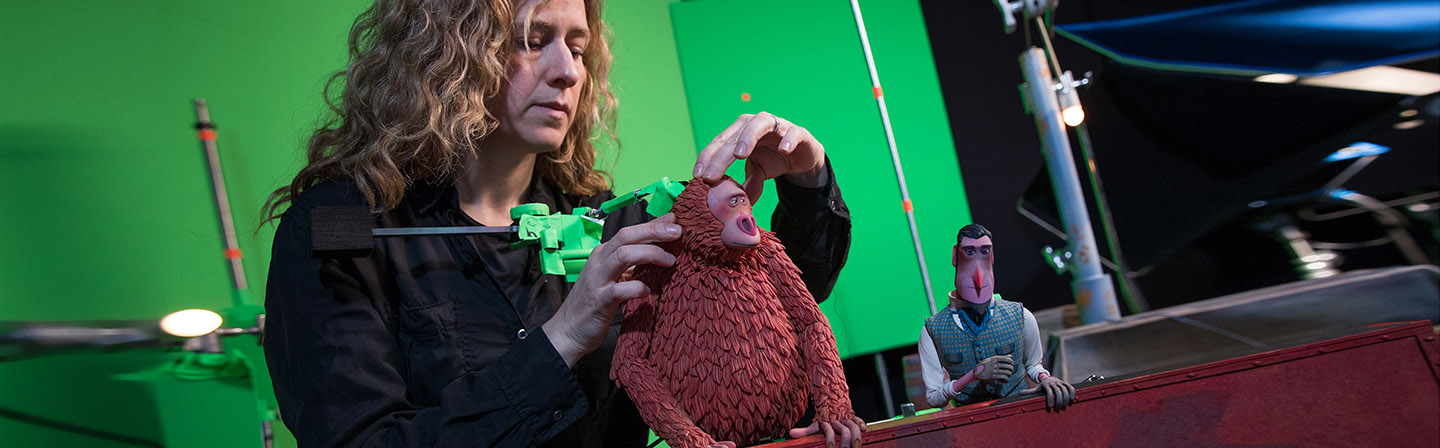

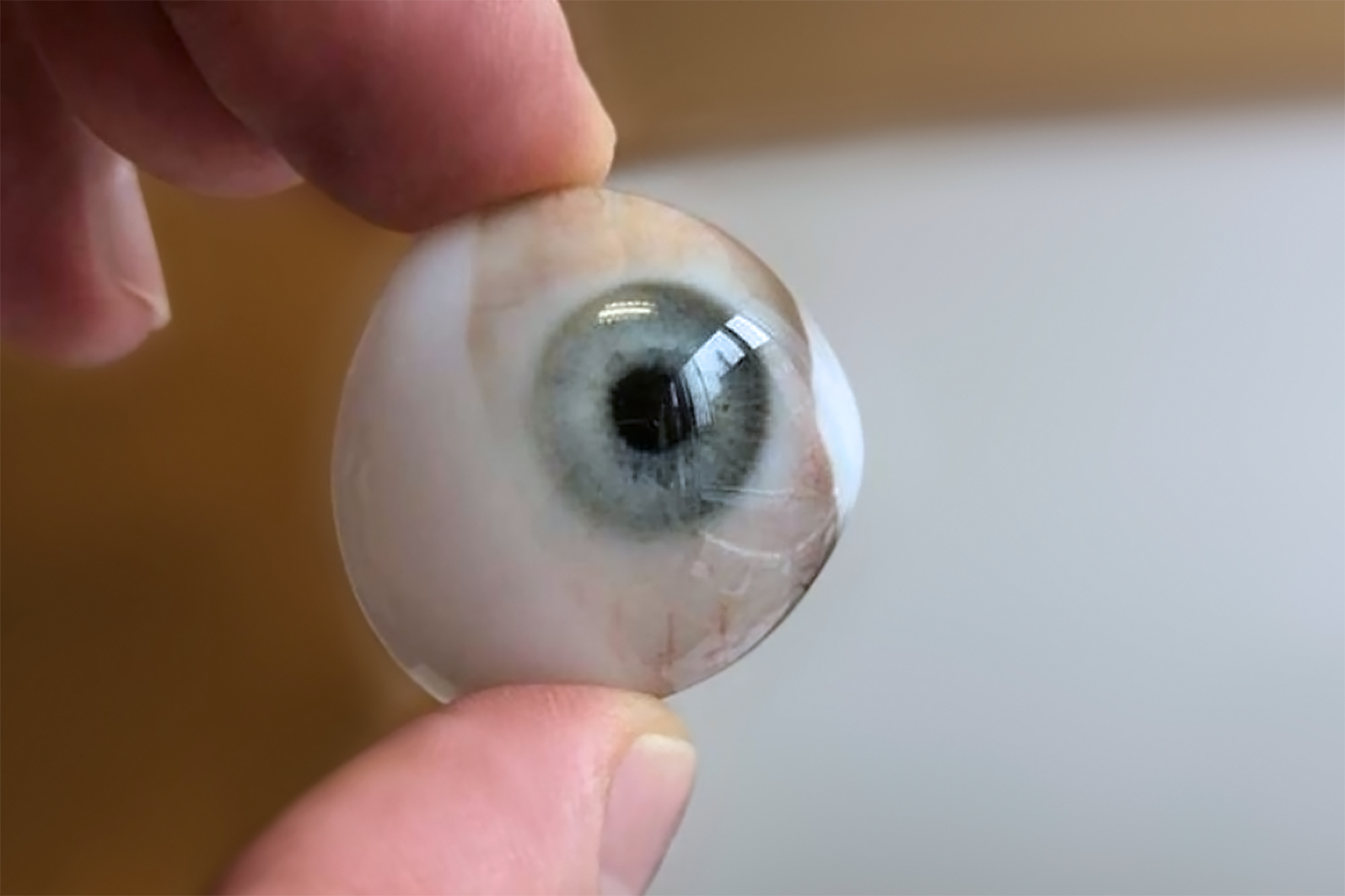

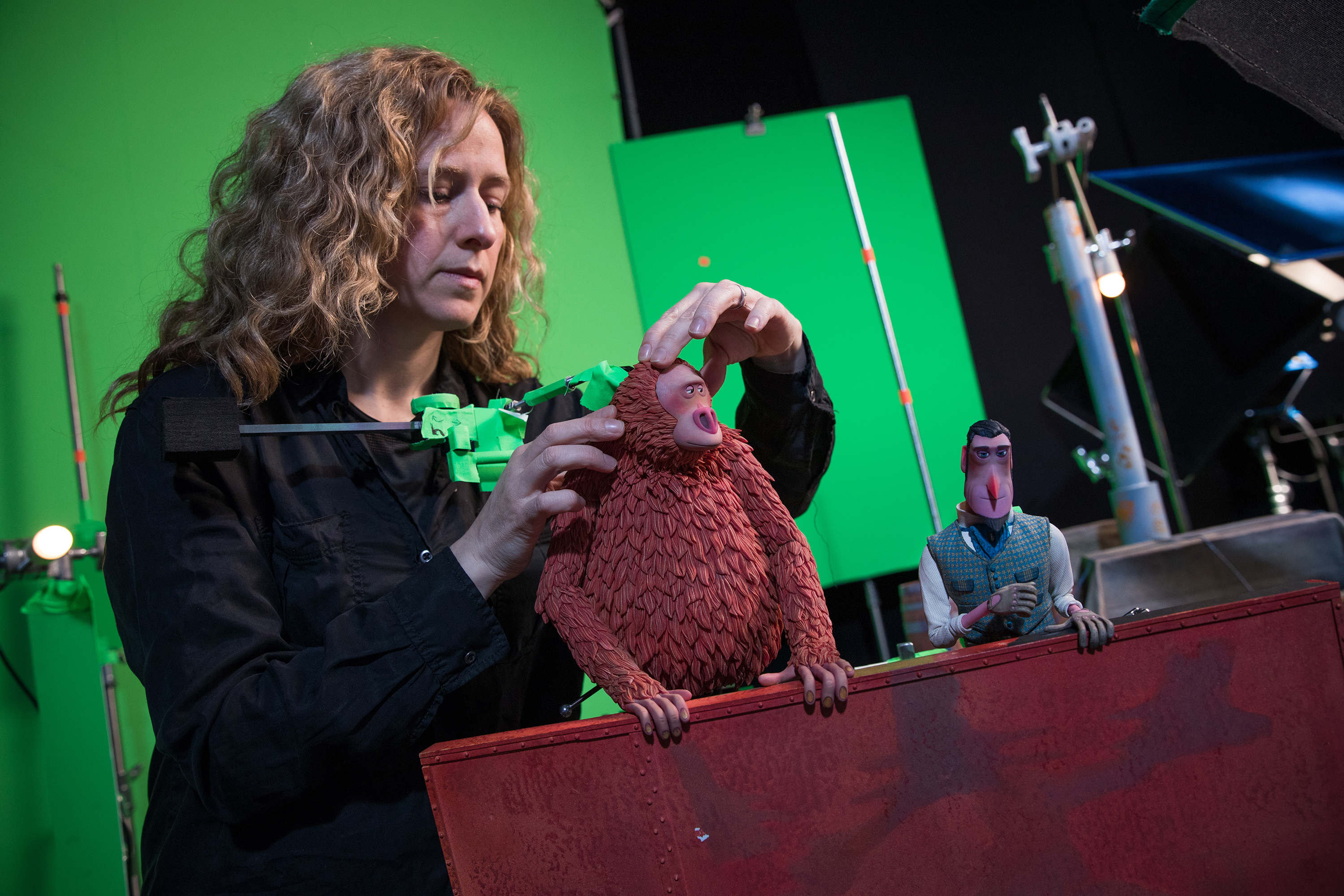

Animation studio and Stratasys customer LAIKA has already recognized the advantage of both technologies. For the stop-motion movie Missing Link, more than 106,000 facial expressions were 3D printed with Cuttlefish®. The biggest challenge was that the creation of lifelike models required many different color gradations – each shade had to match exactly that of the preceding image. Brian McLean, Director of Rapid Prototype at LAIKA: “We’ve been using 3D printers in stop-motion productions since Coraline, the first movie made at LAIKA. For our latest movie, Missing Link, we used Fraunhofer IGD technologies because they allow for unique color consistency and geometric accuracy. By combining the Cuttlefish® software with the Stratasys J750 series 3D printers, we were able to create the most complex color 3D printed surfaces ever produced.” The result was indeed impressive and has been rewarded accordingly: in 2020, Missing Link won a Golden Globe® in the Best Animated Feature category.

Fraunhofer Institute for Computer Graphics Research IGD

Fraunhofer Institute for Computer Graphics Research IGD