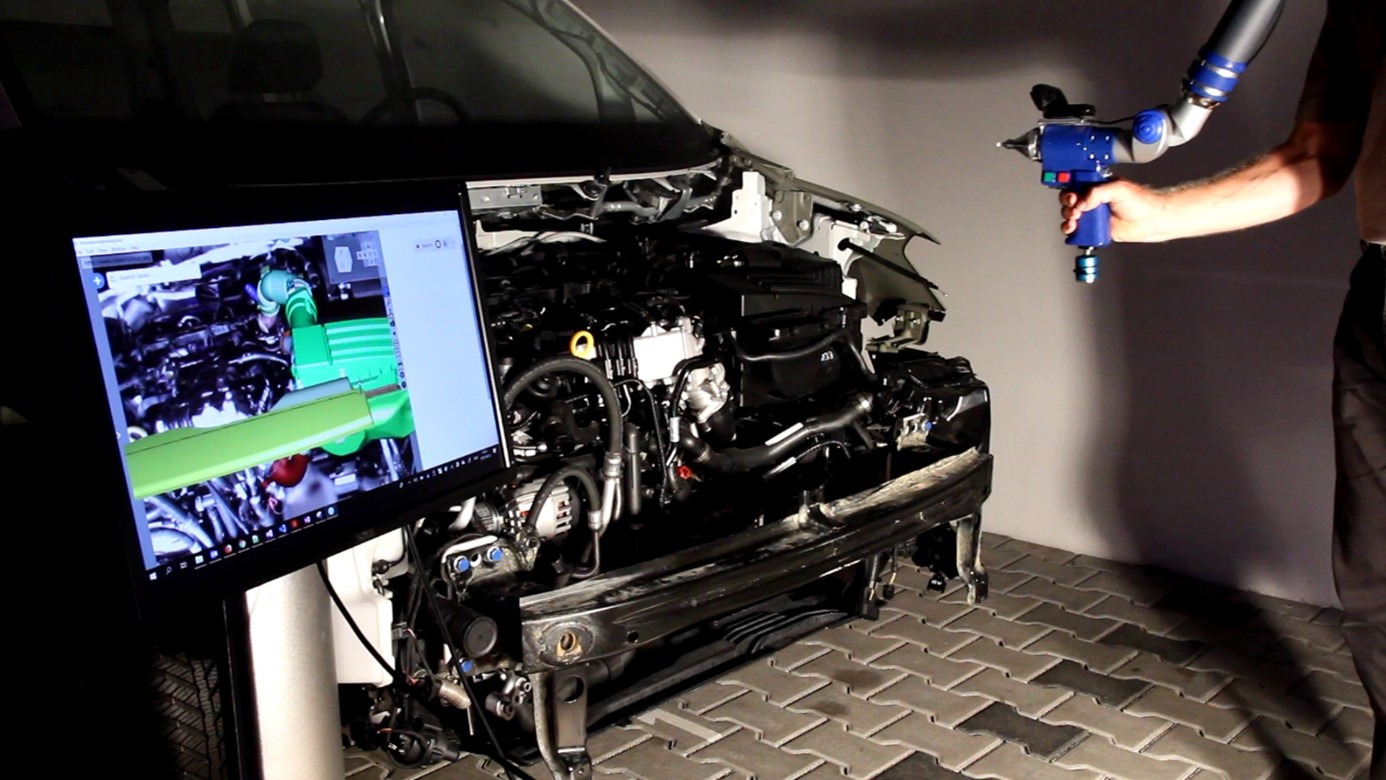

Assessing the manufacturability and optimal layout of flexible parts, ensuring compliance with minimum distance requirements as well as performing nominal/actual comparisons between physical and virtual parts has traditionally been a time-consuming and cost-intensive process. It is possible to increase efficiency if physical components can be analyzed and evaluated alongside virtual CAD data. With its ability to match virtual models of a product with their real-world counterparts, Augmented Reality (AR) can render vital assistance.

Successful collaboration with VW Commercial Vehicles

Working in collaboration with VW Commercial Vehicles in Wolfsburg, Fraunhofer has developed an AR tool that allows the CAD data of a vehicle to be matched with the real thing. The AR overlay displays components that are either unavailable or do not yet exist, and distances between virtual components and real components or the physical surroundings can be measured. The use of AR for compatibility and variance analysis in geometric validation requires an exceptionally high registration accuracy. The project has won acclaim and already been brought to completion.

Fraunhofer Institute for Computer Graphics Research IGD

Fraunhofer Institute for Computer Graphics Research IGD