MARIA research project

Ship maintenance made easy: Fraunhofer institutes work with industry partners to develop maritime service platform

Optimized maintenance and service quality, even on the high seas: A project consortium led by the two Fraunhofer Institutes, IGD and CML, has developed a new service platform to be used by the maritime industry for after-sales applications. By means of augmented reality and intelligent assistance systems, the ship’s crew are able to carry out maintenance work at sea and thereby avoid costly downtime. The researchers presented the results of the MARIA project to a funding committee of the German Federal Ministry of Education and Research (BMBF) in Kassel on Tuesday. The final report has now been published.

Rostock: “It is an enormous advantage if a ship’s crew is able to carry out maintenance work independently while operating away from their home port,” says Anastasiia Novikova, a research associate at the Fraunhofer Institute for Computer Graphics Research IGD. “And this is the approach that we have been pursuing with the maritime service platform. Its partial solutions empower service technicians, even without much prior knowledge, to efficiently ensure the smooth operation of their ship.”

With Fraunhofer IGD as project coordinator, no fewer than eight partners drawn from research and industry have been developing innovative service products based on various use cases. Companies operating in the maritime sector, such as suppliers or shipping lines, are the ultimate beneficiaries, as the technologies enable proactive instead of merely reactive after-sales service. A data hub serves as a registry for all existing partial solutions submitted by the project partners as well as the storage and transmission of application-related data such as telemetries and anomalies. An AR-enabled service assistance system provides technical and commercial communication between the parties involved in maritime after-sales.

Augmented reality for error-free maintenance processes

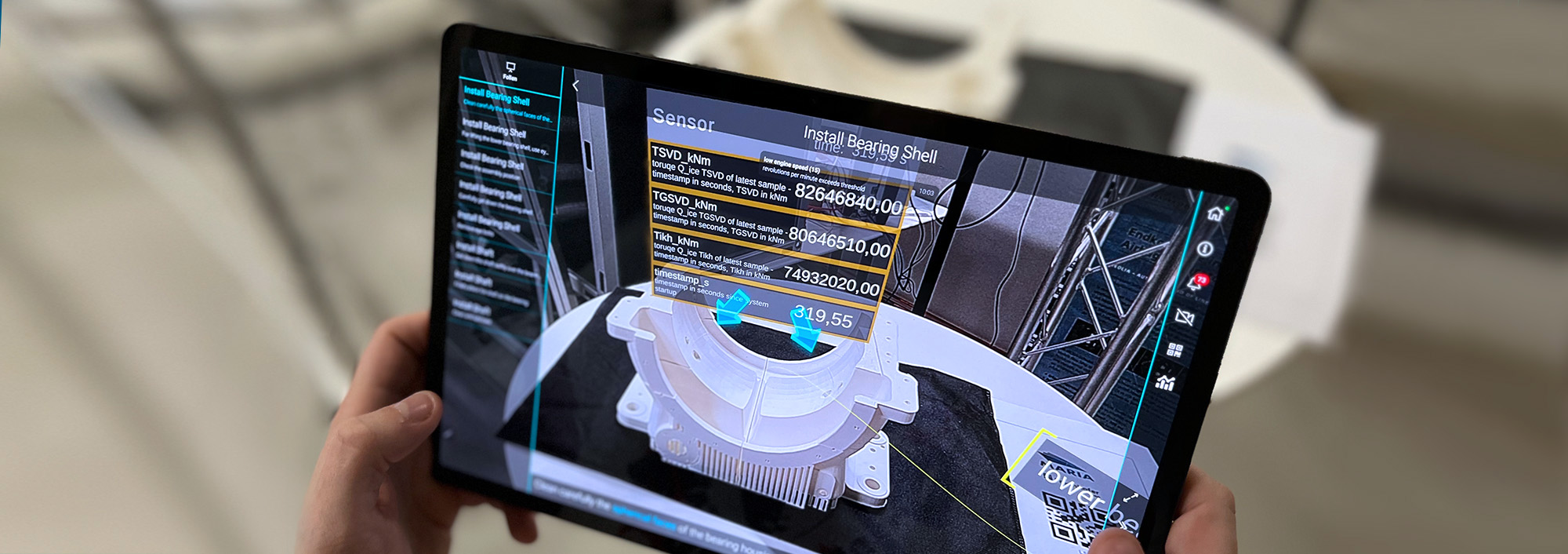

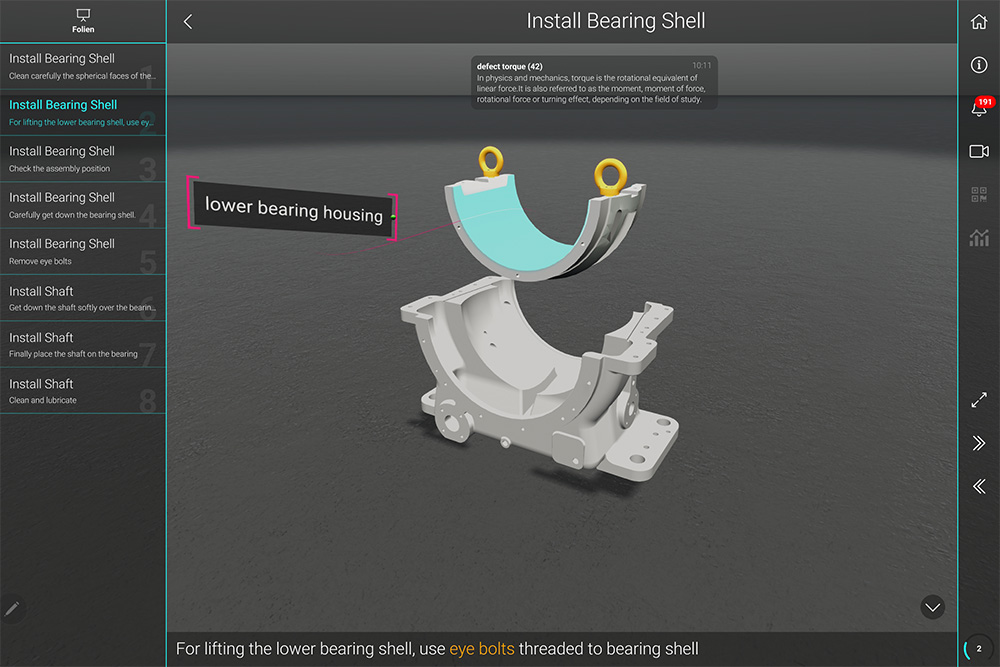

Among the digital services provided is the Machine@Hand mobile application with the Interactive Visualization of Machine-Related Data (IViMaD) module supplied by Fraunhofer IGD. On the basis of 3D model data and assembly instructions from a digital twin that visualizes real-time data of the operating sequence, the crew receives step-by-step instructions for the completion of maintenance tasks. With the help of augmented reality, the fitters on board the ship are guided through the maintenance process. A particular challenge here is that unfavorable lighting conditions and strong movement due to waves make it difficult to use digital assistance systems, and that internet access is frequently intermittent to non-existent. Novikova and her team have optimized the application, taking these environmental factors into account.

The solution provided by Fraunhofer IGD not only reduces training costs, but also combines the proven methodology of a maintenance guide with the real-time visualization of operating data for machinery and other ship components. “This combination allows us to plug the gap between general maintenance procedures and emergency repairs for the first time,” says Novikova. “Furthermore, the service platform makes the cost structure much more transparent, and the entire process of after-sales services is accelerated.”

Market launch planned for early 2024

The project consortium will present the research project, which is funded by the German Federal Ministry of Education and Research, and the final published report at a conference (Sustainably Shaping Data-Oriented Value Creation) in Kassel on 20th June 2023. And even after that, the project team will continue its research. Some sub-projects will be extended, while others will be newly added, all building on what has gone on before within the scope of the MARIA project. Novikova explains the potential: “The integration of technologies such as machine learning, neural networks and big data analytics will enable the efficient detection of vulnerabilities through the evaluation of the ship’s digital twin.” It is expected that the service platform will become available to companies in the maritime industry from 2024 onwards.

Project consortium:

- DRYNET GmbH

- FoP Consult GmbH

- InMediasP GmbH

- Wärtsilä Germany GmbH

- Wiegershaus GmbH

- Zeppelin Power Systems GmbH & Co. KG

- Fraunhofer Center for Maritime Logistics and Services CML

- Fraunhofer Institute for Computer Graphics Research IGD

Fraunhofer Institute for Computer Graphics Research IGD

Fraunhofer Institute for Computer Graphics Research IGD